Tailor-made thermoplastic materials in VR

Thanks to the DigiLab web app, material developers can not only identify compounds for a material with very specific properties in a matter of minutes, but can also literally immerse themselves in the complex data with the help of virtual reality.

How this works, and what advantages three-dimensional space offers users and manufacturers alike, and how materials can be optimized even better with it, is what prefrontal cortex has been researching together with the compounding experts at Merseburg-based Exipnos GmbH and the renowned Fraunhofer Institute for Microstructure of Materials and Systems (IMWS) in Halle (Saale).

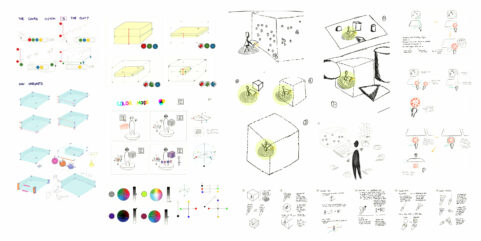

“The requirements for polymers are becoming increasingly complex,” explains Dr. Patrick Hirsch from the Fraunhofer IMWS. For example, users can choose from more than 20 parameters in the browser-based POLYKUM DigiLab® app, from elasticity to density to tensile strength. Even bio-based or recycled materials can be specifically selected. True, usually only three to five are crucial for a particular application. “But even the resulting complexity of the data can hardly be represented on the screen,” he says. “With the help of VR technology, we want to make it much easier to select the right material.” Users can thereby immerse themselves in spatial diagrams, the VR color lab and even molecular structures. All that is needed is a VR headset connected to the computer or even a standalone device – the VR application can be launched simply from the web browser, without a lengthy setup process or the installation of an app.

The research and development project is funded by the state of Saxony-Anhalt and the European Regional Development Fund (ERDF). Investment Bank of the State of Saxony-Anhalt funding code: ZWB 2004/00079.

Funding period: 01.04.2020 – 31.07.2022

PeriodApril 2020 - July 2022

TeamChristian Freitag, Timo Pointke, Elitza Todorova, Tim Schuster

CooperationFraunhofer IMWS, Exipnos GmbH, AppsolutEinfach UG