A virtual glimpse at the future of work

Advancing technology development is opening up fascinating possibilities for how we might work in the future. Let’s imagine we could look into this future and see what tasks and processes are involved in controlling an automatically controlled freight train route might look like.

A train without a driver: The Institute of Transportation Systems at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt e.V.) is researching how exactly this might work and what control and monitoring mechanisms are required. With increasing automation, automatically controlled trains and routes are also becoming a realistic prospect in freight train operations to increase safety and efficiency in rail traffic.

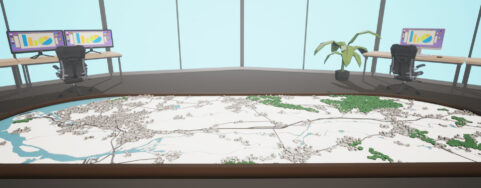

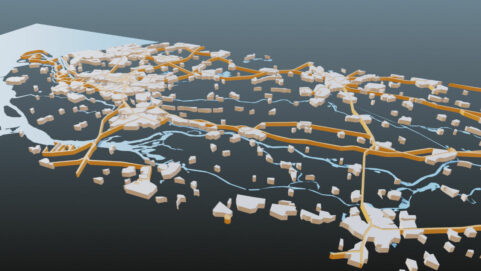

A special focus is placed on the operator’s workplace: Operators play a crucial role by supervising operations for several trains and ensuring that everything runs smoothly. A precise knowledge of the routes, transported goods and individual train details is essential for the operator. A VR prototype makes it possible to simulate this vision and virtually depict future workflows. Users can thus immerse themselves in an immersive 3D environment that gives them a realistic insight into the operator’s tasks and challenges.

The VR application already enables users to experience the complex aspects of automatically controlled freight train operations in a realistic environment. Through this simulation, users can develop a deeper understanding of the processes and interrelationships.

But in perspective, even more is conceivable: By playing out various scenarios in the VR environment, users can improve their reaction times and respond quickly to unforeseen events. This would contribute to an increase in the overall efficiency of the operation. The VR application can thus serve as a training tool to prepare new operators for their tasks. In a virtual environment, they can learn the necessary skills and knowledge without the need for physical infrastructure or real trains. By acting out potentially dangerous situations in the VR environment, users learn how to deal with such challenges. This will help minimize the risk of accidents or operational incidents and increase the safety of automatically controlled freight train operations. The immersive possibilities of VR technology could thus improve workflows, increase efficiency and enhance safety.

Behind the Scenes

In collaboration with DLR’s experts from the rail industry, the scenario presented was developed iteratively. Through regular feedback loops and close collaboration, realistic workflows and challenges were identified and integrated into the VR application. Particular attention was also paid to the visual design: we consciously made sure to find a style that is oriented to the physical workplace and can play to VR’s strengths by superimposing information in the field of view.

Period2022 - 2023

ClientDeutsches Zentrum für Luft- und Raumfahrt e.V.

TeamChristian Freitag, Tim Schuster, Susann Beyer, Ron Kaiser, Felix Reinemann, Felix Herbst

LinksDLR.de